|

|

The St. Gallen EmbroideryA Revolutionary Swiss Stamp |

|

|

|

The St. Gallen EmbroideryA Revolutionary Swiss Stamp |

|

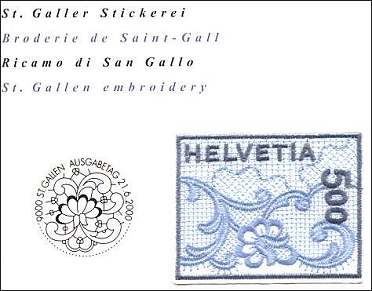

The Swiss post has issued on June 21, 2000 the world's first embroidered stamp. The stamp, shown above, was presented for the first time at the National Philatelic Exhibition in St. Gallen, Eastern Switzerland. This stamp is special because for the first time in the history of philately it doesn't limit itself to show a reproduction of an embroidery, it is a real embroidery, inspired by a traditional design, and appealing to modern manufacturing techniques. The stamp on the right, issued in 1976, shows an embroidery of St. Gall that was made by using the usual printing technology.

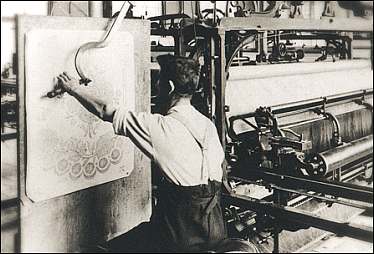

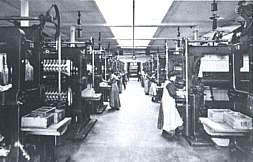

Embroidery has a long and rich tradition in Switzerland. By the turn of the 20th century embroidery has become the most important industry in eastern Switzerland. Over a fifth of the population earned their living on it. Embroidery enjoyed its first heyday as a pure handicraft toward the end of the 18th century. The opening of the American market and the adoption of the new stain stitch technology led to a boom, beginning with 1820. Increased demand and production bottlenecks in hand embroidery stimulated the development of embroidery machines.

|

|

|

At the end of the 19th century, machine embroidery experienced another period of expansion with the introduction of shuttle embroidery. Export reached record levels in 1919. The later worldwide economic crisis hit the embroidery industry particularly hard. Only in 1937 did the situation improve somewhat. Embroidery experienced periods of popularity in the post-W.W.II years peaking between 1962 and 1969 and the late 70s to early 80s. Production figures thereafter diminished again but the export value has steadily increased.

|

|

In contrast to a printed stamp, the embroidery process produces a true three-dimensional stamp. It was embroidered with thread of a superior fabric of polyester quality with a satin sheen. The thread used was specially made and dyed in two tones of blue, being also remarkably strong. The material made was used exclusively for the manufacture of the stamp. Even the self-adhesive coating was developed expressly for the stamp shown above. This multi-layered coating allows removal of the stamp from the envelope without leaving any coating residue. The coating is sealed with peal able foil, the cut in the foil permitting for an easy and fast removal.

|

|

|

The embroidery machine used is a modern Saurer Pentamat 2040. It work at 200 revolutions per minute, producing 340 stamps in one embroidery pass. This machine has 340 needles working simultaneously, with each needle embroidering one stamp. This 340 needles embroider row by row until the fabric is filled, across a width of 9.3 m. Once the embroidery was finished all the linking thread were mechanically removed. Then the stamps, which are still part of a large sheet, are stretched. The self-adhesive coating is applied in multiple passes and finally the stamps are cut of the sheets. As in the case of any piece of embroidery, minimal differences occurred owing to the number of different manufactured processes involved. This is quite common in textile technology and means that each stamp is in fact quite unique.

|

|

|

The designer, Peter Hostettler used a variety of classical laces and embroideries from the private museum of Bischoff Textil AG as sources of inspiration for the stamp. From left to right there are shown:

Rosaline point. The example shown illustrates a band that was worn by men as well as women back to about 1700.

Valenciennes lace. Lace was already being made in the northern French city of Valenciennes early in the 17th century. About 400 bobbins were needed to make the lace shown in the center, worn only by the wealthy nobility during the Rococo period.

Combination lace, that became popular during the 1930s. In was made on a shuttle embroidery machine in one complicated process, whereby machine-produced Valenciennes bobbin lace was used on the top half and the bottom half was machine embroidered.

And now the culmination, the image of my only sheet of four stamps, with a first day cancel in the middle of it.

Notices:

The information of this pages comes from the nice, but quite expensive booklet (shown above) and from the "FOCUS on stamps" 4/2000, a magazine of the Swiss Post.

The manufacturing process for this product, which represent an innovation worldwide, involves a few further specialties which will remain the secret of the manufacturer, the Bischoff AG in St. Gallen.

"Victim" of its success with an innovative product, the Swiss Post could not deliver the above sheet already two months after the issue date. This can be considered a surprise, taking into account its quite high face value, of then CHF 20.00 = about $12.00.

In the meantime the price of the mint sheet jumped to $ 75 - $ 90 on the web. The mint stamp is offered by dealers at about $ 20 - $ 25.

Generally speaking, the National Philatelic Exhibition in St. Gallen, together with the mentioned sheet, have considerably reinvigorated the philatelic activity in Switzerland.

Link: Embroideries from Liechtenstein

| Published:

06/24/2000. Revised:

02/21/20245

. Copyright © 2000 - 2024 by Victor Manta, Switzerland. All rights reserved worldwide. |